Rubber MEGAFLAT

Overview

Rubber MEGAFLAT

Megadyne Megaflat Rubber belts are available in unsupported, knitted and woven structures. Our knitted product offering includes belts that are both elastic and stable in design and available with neoprene or silicone elastomers. Our woven structure is also available in semi-stretch and stable constructions with neoprene elastomer.

Megadyne Rubber flat belt are used in both light power transmission applications as well as conveying of small parts and light weight products.

Megadyne Rubber flat belts are used in application as is or make the perfect foundation for covers and coating additions.

Features

Rubber MEGAFLAT: wide variety of coatings means wide range of applications possible.

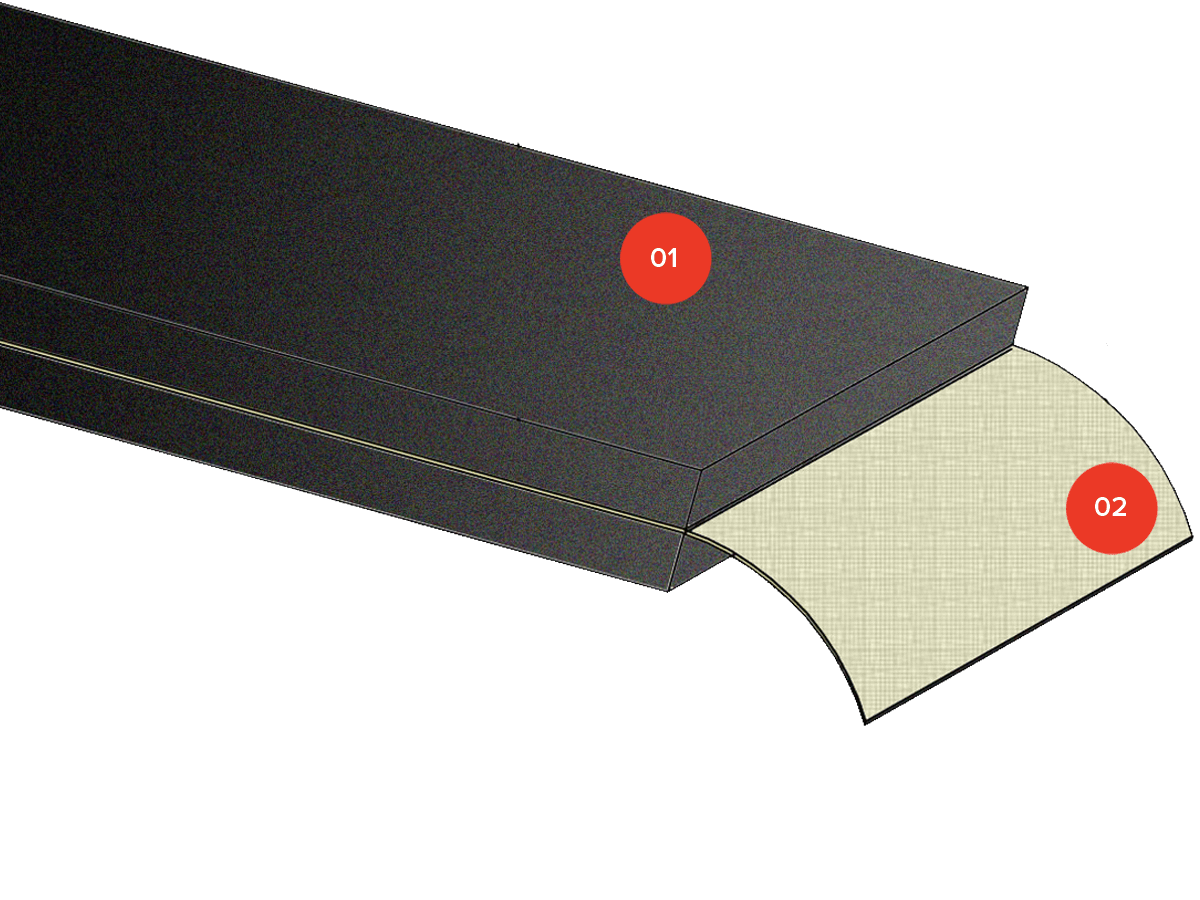

Main components

01 / BODY

Coating for drive or transport side- neoprene, silicone or gum rubber

02 / FABRIC

Knitted or woven substrate with reinforcement material that include polyester, aramid/polyester, nylon, polyester/cotton and aramid/polyester

Mechanical and chemical properties

- high flexibility

- small pulley diameters

- dimensional accuracy

- high speed

- energy efficient

- low vibration and noise

- high friction surface

- good chemical and ozone resistance

- uniform elongation values

- antistatic

- Series “T” belt working temperature -25°C / +100°C (T75 and T200: -30°C / +110°C)

Main Applications by Industry

Range

T75, T108, T110, T120, T150, T155, T200.