Choosing Synchronous Belts

Why Choose Megadyne

for Synchronous Belts

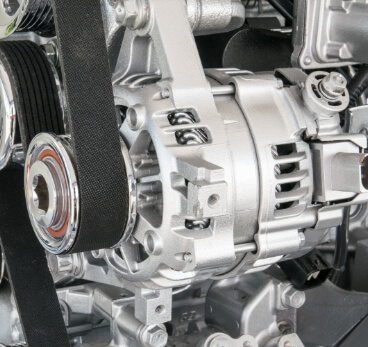

Many industrial systems use synchronous belts to power electric motors and other driven equipment. A modern alternative to traditional belts, the positive engagement that powers these belts heightens power and minimizes the need for maintenance. The latest technology and high-quality materials deliver a product that offers greater capacity and quiet, uninterrupted operations.

The right synchronous belt and proper alignment on the drive system will ensure a belted drive's longevity and equipment safety. That's why it's essential to partner with a company specializing in belting systems to determine the correct belt solution for your needs. At Megadyne, we've been providing cutting-edge drive belt solutions since 1957.

The two main timing belt types are rubber and polyurethane synchronous belts.

Options for Every Application

Options for Every Application

Megadyne provides synchronous belt solutions for a wide range of applications and industries. Some industries we work with include material handling, elevators, machine tools, food industry equipment, packaging, fitness,

wood, marble, and ceramics. We serve original equipment manufacturers and aftermarket distributors, and engineered belts are the true pride of Megadyne.

Purchasers of our customized timing belts receive direct expertise from the beginning. They are always impressed with the final product of customized power transmission belts and accessories, which meet the exact requirements of their machines.

Continuous Improvement

Megadyne's investment in skilled designers and engineers allows us to provide innovative, power-driven synchronous belts. Our team thoroughly analyzes and studies industrial processes to develop new solutions and upgrades for enhanced system performance.

Our Titanium timing belt is the latest high-performing rubber-based timing belt. It significantly improves "specific power" capacity and offers new application opportunities beyond that of alternative systems.

Sustainability

Sustainability

Megadyne is built from a group of like-minded people who cherish the world's beauty and commit to preserving it for future generations. Accordingly, we produce solutions that last longer, save energy, and lower our customers' carbon footprint.

We have expanded our synchronous belt options with the Megadyne MegaEco range of sustainable belt solutions for power transmission systems. Our MEGAFLEX MegaEco Biobased and MEGALINEAR MegaEco Biobased products use a polymer made with vegetable products and other sources for an eco-friendly alternative. Megalinear MegaEco Biobased AT10 is available to support your company's sustainability goals.

Meticulously Crafted Polyurethane Timing Belts

Many applications use Megadyne's polyurethane timing belts because of their numerous benefits, including rust, wear, and chemical resistance.

Polyurethane synchronous timing belts crafted by Megadyne include:

-

Megapower

-

Megapower 2

-

Megaflex

-

Megalinear

-

Megapower

This belt is manufactured using a unique thermoset molding process within a tight tolerance range for consistent synchronous belt length and thickness. Thanks to its combination of high-grade polyurethane and various grades of steel cords, it offers excellent dimensional stability.

MEGAPOWER timing belts perform at the highest physical and chemical levels. They are ideal for light synchronized and stepped drives in office automation and domestic appliance applications

-

Megapower 2

The new generation of thermoset polyurethane timing belts is designed to handle the most demanding applications. Megadyne's unique molding process combined with a high-performance compound led to the creation of MEGAPOWER 2. The innovative timing belt offers 30% greater performance, more transmittable power, and excellent dimensional stability.

-

Megaflex

Megadyne's Research and Development team developed MEGAFLEX timing belts to deliver exceptional performance. This belt is manufactured using thermoplastic polyurethane combined with continuous spiral steel cords. The nylon-coated teeth enhance the belt's running properties for specific applications and reduce the noise frictional coefficient.

MEGAFLEX has enhanced running properties and is best suited for power transmission and bearing high loads and high speeds (up to 10.000 RPM). We can add extra thickness to the belt's back to protect against aggressive or heavy products.

-

Megalinear

MEGALINEAR is manufactured in thermoplastic polyurethane for superior wear resistance and abrasion resistance. Tight tolerances ensure reliability and excellent dimensional stability.

Adding a nylon coating to the teeth and/or back of the timing belt during production can enhance running properties for specific applications. In contrast, an extra thickness of polyurethane on the belt's back can provide extra protection against aggressive or heavy products.

Expertly Engineered Rubber Endless Timing Belts

Megadyne's rubber endless timing belts are manufactured using the latest technology. Options are available with single or double-sided teeth and imperial, RPP, and RPC profiles. Rubber timing belts are a lower weight than other synchronous belts, making them easier to install and change while increasing energy efficiency.

We have expanded our range of products to include the following options:

-

MEGADYNE MEGASYNC™ IMPERIAL SYNCHRONOUS

-

MEGADYNE MEGASYNC™ STD, HTB

-

MEGADYNE MEGASYNC™ RPP3 RPP5 RPP8 RPP14

-

MEGADYNE MEGASYNC™ SILVER3 and GOLD2

-

MEGADYNE MEGASYNC™ TITANIUM

-

MEGADYNE MEGASYNC™ IMPERIAL SYNCHRONOUS

These synchronous belts feature a trapezoidal tooth profile and nylon fabric to protect the tooth surface. Megadyne Megasync's polychloroprene teeth offer accurate meshing, while fiberglass reinforcement provides minimal elongation.

-

MEGADYNE MEGASYNC™ STD, HTB

These belts have a curvilinear tooth profile while offering the same running properties and reliable performance as RPP belts.

-

MEGADYNE MEGASYNC™ RPP3 RPP5 RPP8 RPP14

This timing belt features chloroprene rubber to help with wear resistance and increase the belt's service life. An RPP parabolic tooth profile increases graduated pressure over tooth height. The nylon fabric protection on the tooth surface also has self-lubrication properties, while fiberglass reinforcement offers minimal elongation and greater flexibility.

-

MEGADYNE MEGASYNC™ SILVER3 and GOLD2

The belt has a higher tooth jump resistance and increased tooth shear resistance for quieter and maintenance-free operation. It offers up to 98% drive energy efficiency and is interchangeable with parabolic and deep pulley profiles.

The rubber timing belt allows you to upgrade an existing transmission without changing pulleys. Its antistatic properties conform to ISO 9563 (BS 2050), making it an excellent option for backside idlers.

-

MEGADYNE MEGASYNC™ TITANIUM

The innovative new materials of Titanium offers the following:

- Up to 30% basic power capacity over the previous top-of-the-range timing belts. The belt's wide range of operating temperatures makes it the only solution for extreme working conditions.

- It is one of the quietest systems on the market due to its noise reduction with a rubber matrix and teeth. Users enjoy significantly reduced noise compared to drive systems that use other materials.

- An advanced RPC profile helps the system achieve a high-power capacity drive with excellent dimensional stability.

Our Titanium product offers a fully functional interchange with the most common existing deep pulley tooth profile systems, including HTD, RPP, PGGT, and PCGT profiles. It allows the user to upgrade existing drives without needing to replace pulleys. Its antistatic properties also follow ISO 9563 (BS 2050) guidelines.

Contact Megadyne for Synchronous Belts

Many applications rely on rubber or polyurethane synchronous belts. The right timing belts can improve performance, noise level, and more.

As an industry leader in high-quality industrial timing belts, Megadyne provides rubber and polyurethane timing belts to improve the safety and efficiency of your system while meeting industry requirements. We also provide timing belts for many international original equipment manufacturers and aftermarket distributors and made-to-order products for our clients.

Contact us today to find reliable timing belts and customized solutions to meet your needs.