MEGASYNC™ Gold2

Overview

MEGASYNC™ Gold2

MEGASYNC™ Gold2 has been developed to provide a more powerful version of RPP and Silver belts. It is suitable for a very wide range of applications in power transmission. This type of belt combines the advantages of gears and roller chain drives, minimizing the drawbacks of both.

Gold2 belts feature the RPC profile, designed also to be interchangeable with existing deep groove profiles and to run on pulleys according to ISO 13050. MEGASYNC™ Gold2 belts are also antistatic according to ISO 9563.

Features

Megadyne MEGASYNC™ Gold2 belts have been developed to give a more powerful alternative to RPP and Silver3 belts to compete against high-performance transmission systems using chains and gears, that always have a disadvantage in terms of weight, noise, lubrication and maintenance costs.

MEGASYNC™ Gold3 can be used to improve and easily upgrade already existing drives working with both MEGASYNC™ RPP and MEGASYNC™ Silver.

The design of Gold2 timing belts offers the possibility to keep using the same RPP pulleys.

MEGASYNC™ Gold2 14M belts have two nylon plies on the teeth to:

• Improve belt resistance to wearing

• Reduce friction and noise levels.

Because of these features, replacing an MEGASYNC™ RPP or Silver3 with an MEGASYNC™ Gold2 can:

• Reduce belt width thanks to the higher power rate; this allows also to reduce the required pulley width. They both lead to a significant transmission weight reduction;

• Reduce the pulley diameters thanks to the higher power rate; this leads to a lower belt linear speed and to the consequent noise reduction.

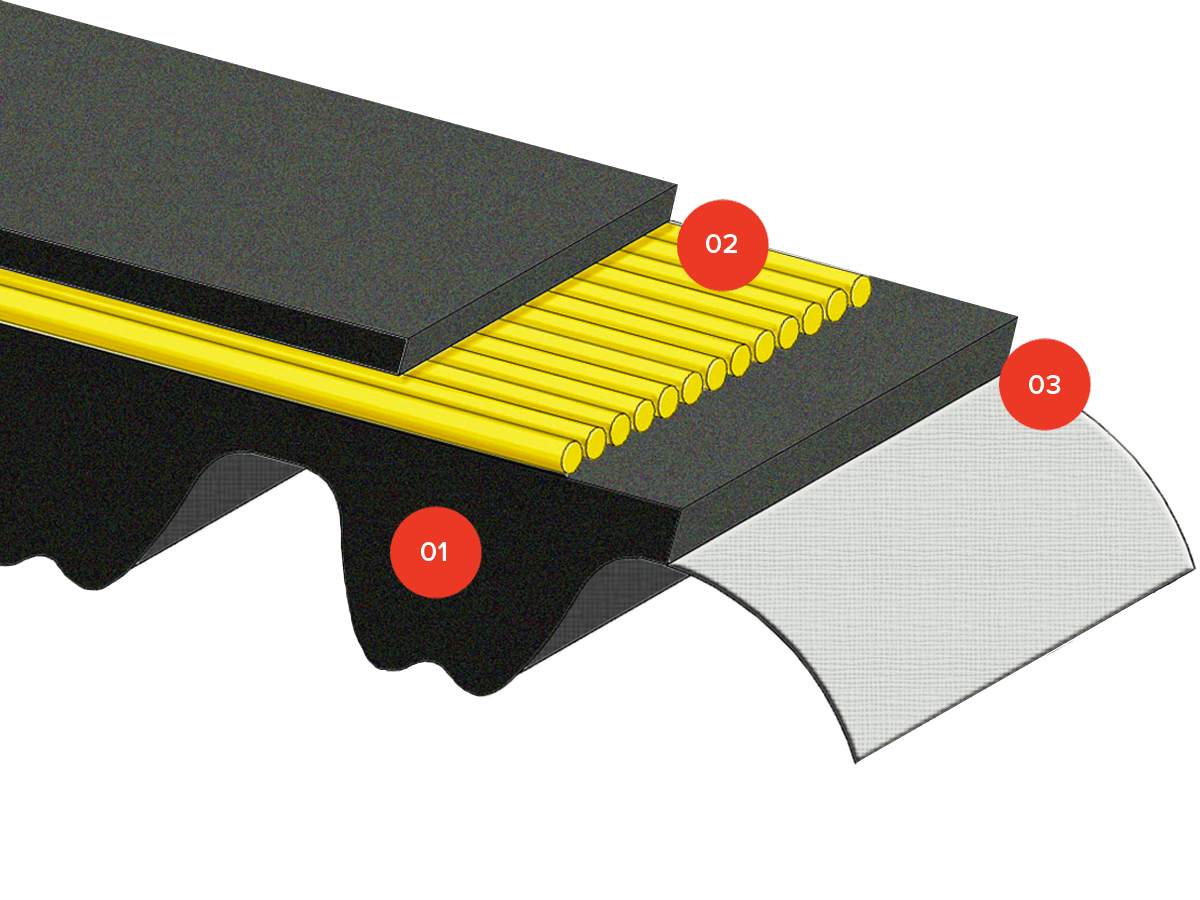

Main components

01/ BODY

High-performance NBR

02 / CORD

MEGASYNC™ Gold2 features a high performance K-glass cord.

03 / COVER

MEGASYNC™ Gold2 has dual layer nylon (for 14M) and a single layer nylon (for 8M): self-lubricating, low friction, extended life.

Mechanical and chemical properties

• Tooth Pitch Code: GLD2 5M, GLD2 8M and GLD2 14M.

• RPC tooth profile, known for its low-noise characteristics.

• Cord: Higher power capacity Fiberglass Cords with excellent dimensional stability.

• Compound: a high-performance compound gives oil and heat resistance.

• Tooth Cover: graphite impregnated fabric coated with a film provides low friction and durability.

• Antistatic properties: conforms to ISO 9563 (BS 2050) standard.

• Operating temperatures: 25 °C up to +80 °C (Max peak: 100 °C).

• Available in any width.

• On demand: GLD2 8M DD and GLD2 14M DD (Dual-Sided).