MEGALINEAR

Overview

MEGALINEAR

MEGALINEAR open length timing belts are manufactured in thermoplastic polyurethane, giving superior wear and abrasion resistance. Various grades of steel cords offer good running characteristics, even with high tractive efforts.

Manufactured to tight tolerances, MEGALINEAR delivers reliability and excellent dimensional stability. The addition of a nylon coating on the teeth and/or on the back of the belt during production enhances the running properties for specific applications.

An extra thickness of polyurethane is also available on the back of the belt, offering extra protection against aggressive or heavy products.

WHY MEGALINEAR?

- MEGALINEAR is compatible for fabrication with other thermoplastic materials.

- Many profiles and coatings are possible to suit specific applications.

- Normally used in linear motion drives, it can be supplied as open end rolls or as endless jointed belts.

- MEGALINEAR belt working temperature: -25°C/+80°C

Features

MEGALINEAR is compatible for fabrication with other thermoplastic materials.

Many profiles and coatings are possible to suit specific applications.

Normally used in linear motion drives, it can be supplied as open end rolls or as endless jointed belts.

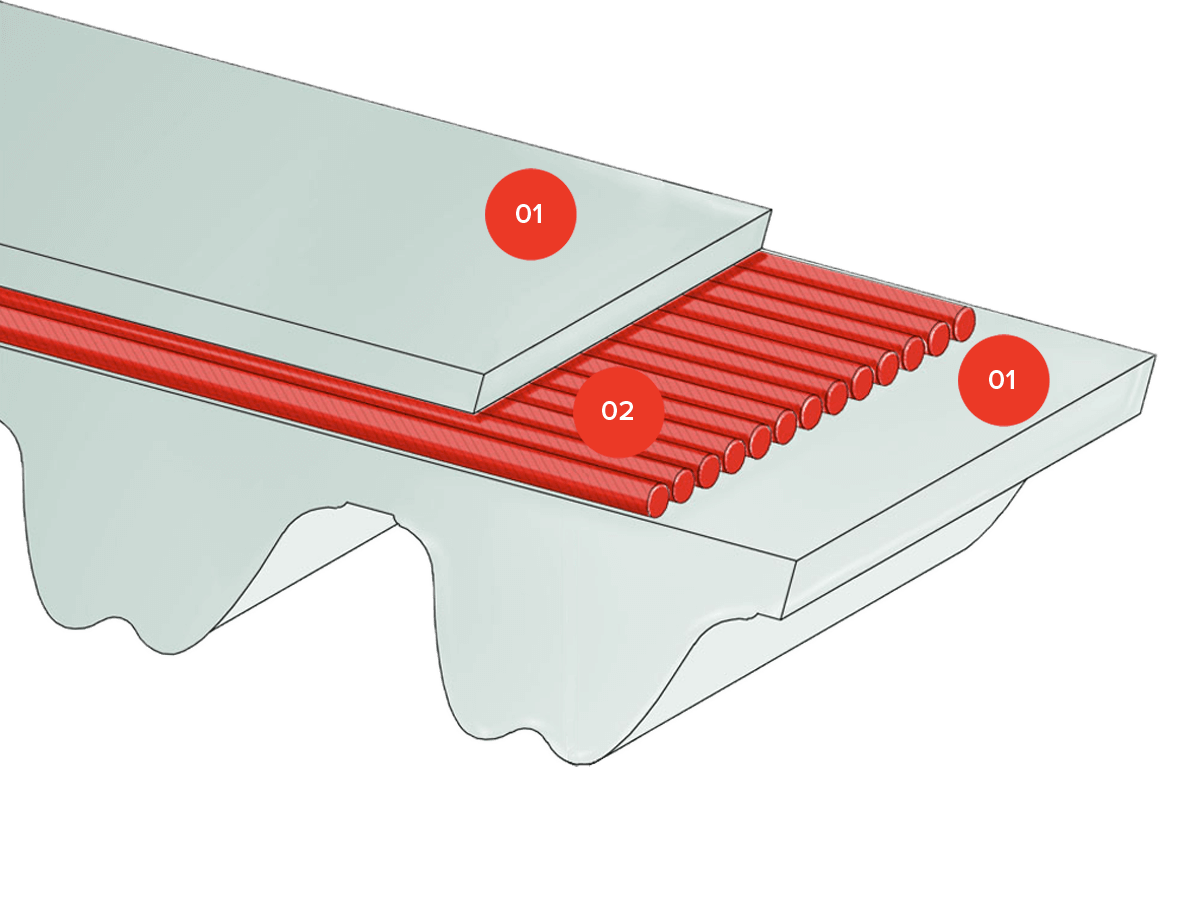

Main components

01 / BODY

The body of the belt is white thermoplastic polyurethane 92 ShA, characterized by high levels of wear resistance even in the presence of shock and surge loading.

02 / CORD

High strength S and Z parallel zinc coated steel tension members allow high breaking loads and extremely low elongation.

Mechanical and chemical properties

- constant dimension and length

- high flexibility

- high resistance to oils, greasers, ageing, hydrolysis, ozone

- free maintenance

- linear speed up to 20 m/s

- MEGALINEAR belt working temperature -25°C/+80°C