MEGAFLEX XMD

Overview

MEGAFLEX XMD

A new game changer

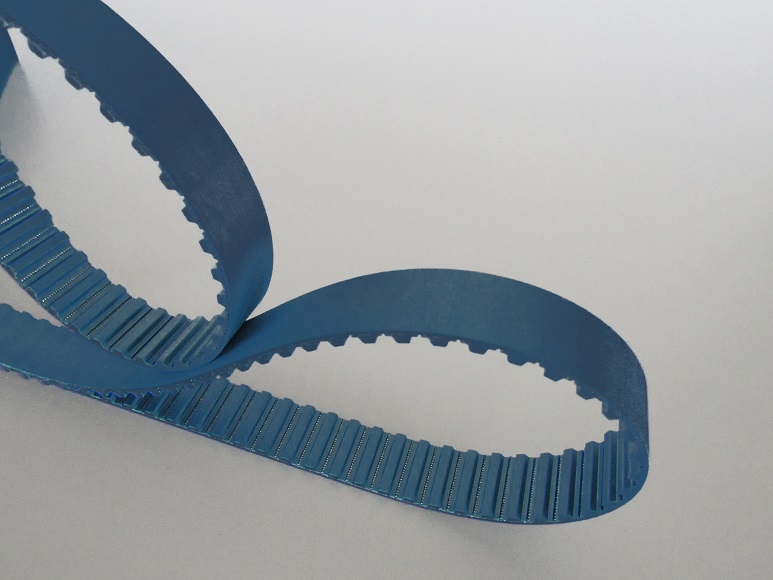

Belt and cleat fragments from all Megalinear XMD and Megaflex XMD belts can be spotted by metal and x-ray detectors, thanks to a special compound used in the manufacture of these timing belts and their accessories. Therefore, any Food Contact Timing Belts (open end, endless joined, and truly endless) constructed with this compound are detectable. This Food Safety feature is in addition to other special hygienic design features that include sealed edges and the use of blue as a contrast colour. Therefore, all Food Contact Timing Belts (open end, endless joined, and truly endless) constructed with this compound are detectable!

Megaflex timing belts are manufactured in thermoplastic polyurethane, with continuous spiral steel cords. this type of belt, developed by our research & development, offers good running characteristics and high traction loads.

They are especially suited for power transmission and conveying with high loads and high speeds (up to 10.000 rpm). The addition of a nylon coating on the teeth during production enhances the running properties for specific applications and reduces the noise frictional coefficient. An extra thickness of special coating is also possible on the back of the belt offering extra protection against aggressive or heavy products.

Megaflex belts are truly endless, enabling them to deliver exceptional performance.

Features

MEGAFLEX is manufactured to the customer’s length specification.

This belt is especially suitable for power transmission and conveyor applications with high load and high speed.

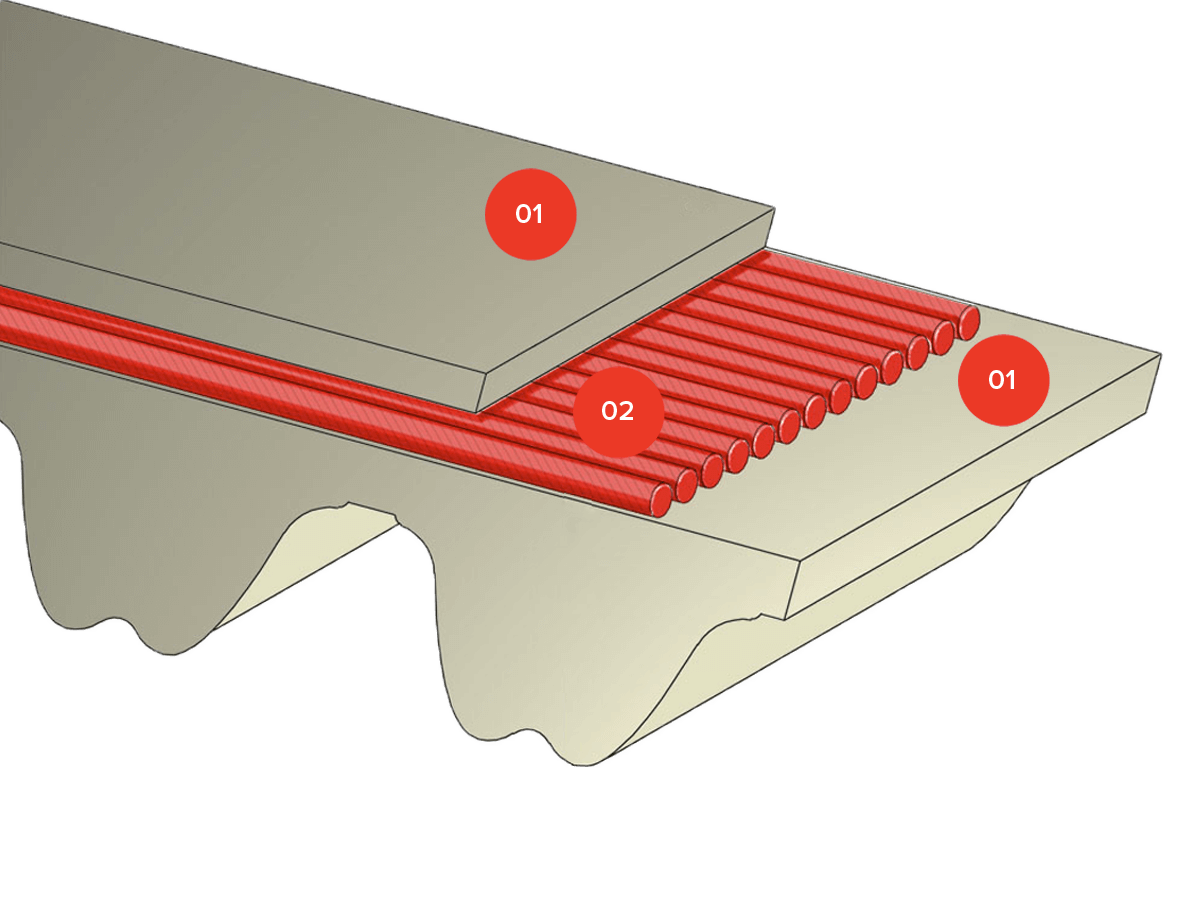

Main components

01 / BODY

The body of the belt is white thermoplastic polyurethane 92 ShA, characterized by high levels of wear resistance even in the presence of shock and surge loading.

02 / CORD

High strength helically wound zinc coated steel tension members allow high breaking loads and extremely low elongation.

Available with Kevlar, Stainless steel, HF, HP, HPF, HP stainless steel.

Mechanical and chemical properties

Characteristics:

- Special detectable dark blue polyurethane compound

- Standard cords: S and Z torsion Kevlar for Megalinear FC; Stainless steel for Megaflex FCM and Megalinear FCM

- Standard splice method by finger splice

- Customizable with cleats, made of the same detectable thermoplastic compound and applied by welding.

- constant dimension and length

- high flexibility

- high resistance to oils, greases, ageing, hydrolysis, ozone

- maintenance free

- linear speed up to 20 m/s

- MEGAFLEX belt working temperature -25°C/+80°C