Drive Selection Software for Rubber Synchronous & V-Belt Drives

We are announcing yet another upgrade to the Megadyne Product Selection Pro drive design software available online exclusively from the Megadyne website.

With the introduction of the new Ultra High Torque Synchronous MEGASYNC™ Titanium belt, we have revised the software to include this new belt, which in addition to being the highest power density belt available, also has anti-static properties. Use Product Selection Pro to design a MEGASYNC™ Titanium drive and solve problems on your toughest applications!

Note: It will still be possible to analyze existing drives using the Platinum product, but Platinum has been removed from the New Drive Design feature, as it will eventually be superseded by MEGASYNC™ Titanium.

New Drive Designs

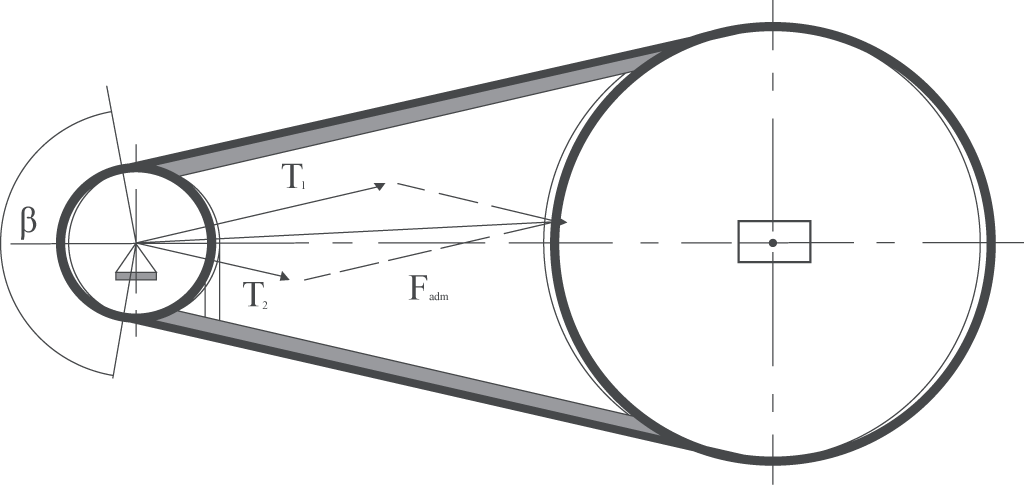

The software permits users to design two pulley drives based on standard, readily available components (belts, pulleys & bushings). Multiple drive solutions are sorted by relative cost (least to most expensive). Drive solutions are archived and can be printed and/or emailed to customers.

V-Belt sections included in the software

-

3L, 4L, 5L

-

A, B, C, D

-

AX, BX, CX

-

3V, 5V, 8V

-

3VX, 5VX

Synchronous belts included in the software

-

RPC MEGASYNC™ Titanium 8M & 14M

-

RPP Gold 8M & 14M

-

RPP Silver 2 8M & 14M

-

Silver 5MS

-

RPP Bronze 3M, 5M, 8M & 14M

-

Imperial MXL, XL, L, H, XH, XXH

The software contains a set of “basic” inputs and an optional set of “advanced” inputs, which allow further refinement of the drive solutions selected by the program.

After entering the basic inputs (and, optionally, the advanced inputs), click the “Find Solutions” button. The program will examine all combinations of sprockets and belts, and produce a list of the top drive solutions, sorted by relative cost, that meet all of your input criteria. You can also sort by clicking on the headers of the various columns.

Info included in the list of top drive solutions is:

-

Pulley/Sprocket part numbers and pitch diameters

-

Driver and driven bushing part numbers (if required)

-

Belt part number and quantity required

-

Actual service factor of the drive

-

Actual center distance of the drive

-

Actual driven speed of the drive

-

Relative cost of the drive

-

Tensioning data (also useful for determining correct tension values for existing drives)

All drive solutions are assigned unique ID numbers. To retrieve (open) a specific drive, click on its ID. This will open the inputs/results page for that solution, allowing you to view the solution, print it, or perhaps change some of the inputs and re-run it (generating a new drive solution.) You can also save the drive design with the “print to pdf” feature and archive and/or email the document

You can locate a drive solution in the archive by scrolling through the list of solutions, or by directly finding it (if you know the ID number) by typing the number directly into the ID column’s Search box. If you want to open the drive solution in a new tab in your web browser, right-click on the ID number link, and choose “Open link in new tab” (your web browser might display slightly different wording). This is sometimes useful if you wish to look at multiple solutions, and don’t want to open the Search Archive dialog each time.

Existing Drive Analysis (Synchronous or V-Belts)

In addition to the capability of designing new drives from scratch, the software allows the analysis of existing drives. This feature is helpful in troubleshooting existing drive problems, as it can identify whether a drive was properly engineered from the start.

Energy Savings Calculator

Select "New Solutions" from the home page, then "Energy Savings Calculator". Just like with the other features of the program, you are able to print, email and archive your energy saving calculations.

The Energy Savings Calculator gives the following information:

-

Annual Kilowatt Hours

-

Annual Energy Cost

-

Annual Energy Savings

-

Payback in months

The Energy Savings Calculator shows the economic impact from simply upgrading wrapped v-belts to raw edge cog v-belts or gaining maximum efficiency with a complete change to a non-slip synchronous drive system.

Tension Calculator for Existing Drives

For existing drives, users can calculate the correct tension for their existing synchronous and v-belt drives before performing the tensioning maintenance. After clicking on the "New Solutions" button on the home page, users can select “Tension Calculator for existing drives”.

Click here to start the registration process.