Courroies hybrides Pro Plus

Aperçu

Courroies hybrides Pro Plus

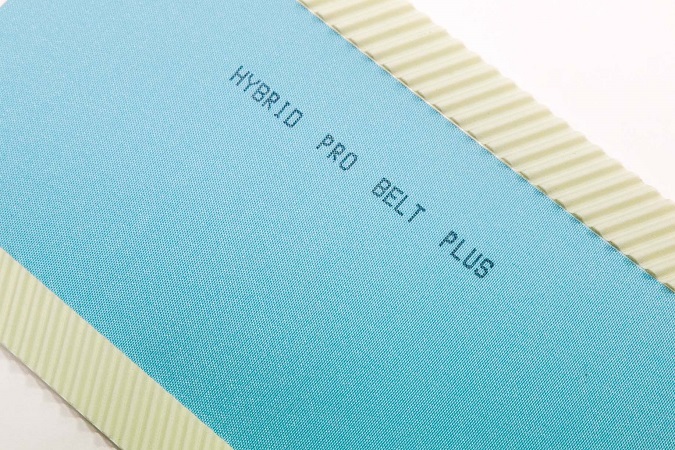

The HYBRID PRO BELT PLUS is part of the HYBRID BELTS SERIES: innovative belts with unique features within the market, combining successfully the positive features of timing belts with and conveyor belts.

The main feature of HYBRID PRO BELT PLUS is the application of one, two or more QST timing belt at the edges of a polyurethane conveyor belt, in order to achieve different benefits.

Compatible for fabrication with other thermoplastic materials, many profiles and coatings are possible to suit specific applications.

Fonctionnalités

- Driven speed up to 550 mt/min

- Greater productivity

- Long belt life, because the conveyor belt works without traction loads

- Cost reduction - Less energy absorption (about 30%)

- Energy saving

- Extremely customization, covering and special reworking

- Taylor made

- Improved reduction in noise level

- Less noisy

Composants principaux

Conveyor Belt: PUCON – Thermoplastic Polyurethane; SILCON - Silicone

Material: PU / SIL

Type of fabric: PET, rigid

Timing belt: MEGALINEAR QST (Quiet Self Track) - Thermoplastic polyurethane 92 ShA with steel cords and standard tooth in NFT

Caractéristiques techniques et mécaniques

- Smooth starting and running

- More compact dimension of pulleys

- Compact drive, more flexibility

- Less noisy

- HYBRID PRO BELT PLUS working temperature: -25° / +80°

Profils

For the conveyor belt:

The range includes different size, fabric, compounds, colors and patterns.

For the timing belt:

Pitches: QST5, QST8, QST14

Production width: Maximum 1000 mm

Minimum roller diameter: 80 mm