MEGALINEAR MLR-45

Descripción general

MEGALINEAR MLR-45

Megadyne introduces MEGALINEAR MLR-45: a durable, reliable and low-maintenance engineered belt for extended life in demanding applications in a Logistics warehouse.

In the realm of modern intralogistics, power transmission belt systems must meet rigorous criteria: reliability, durability, and efficiency. MLR-45 meets all of the criteria and more!

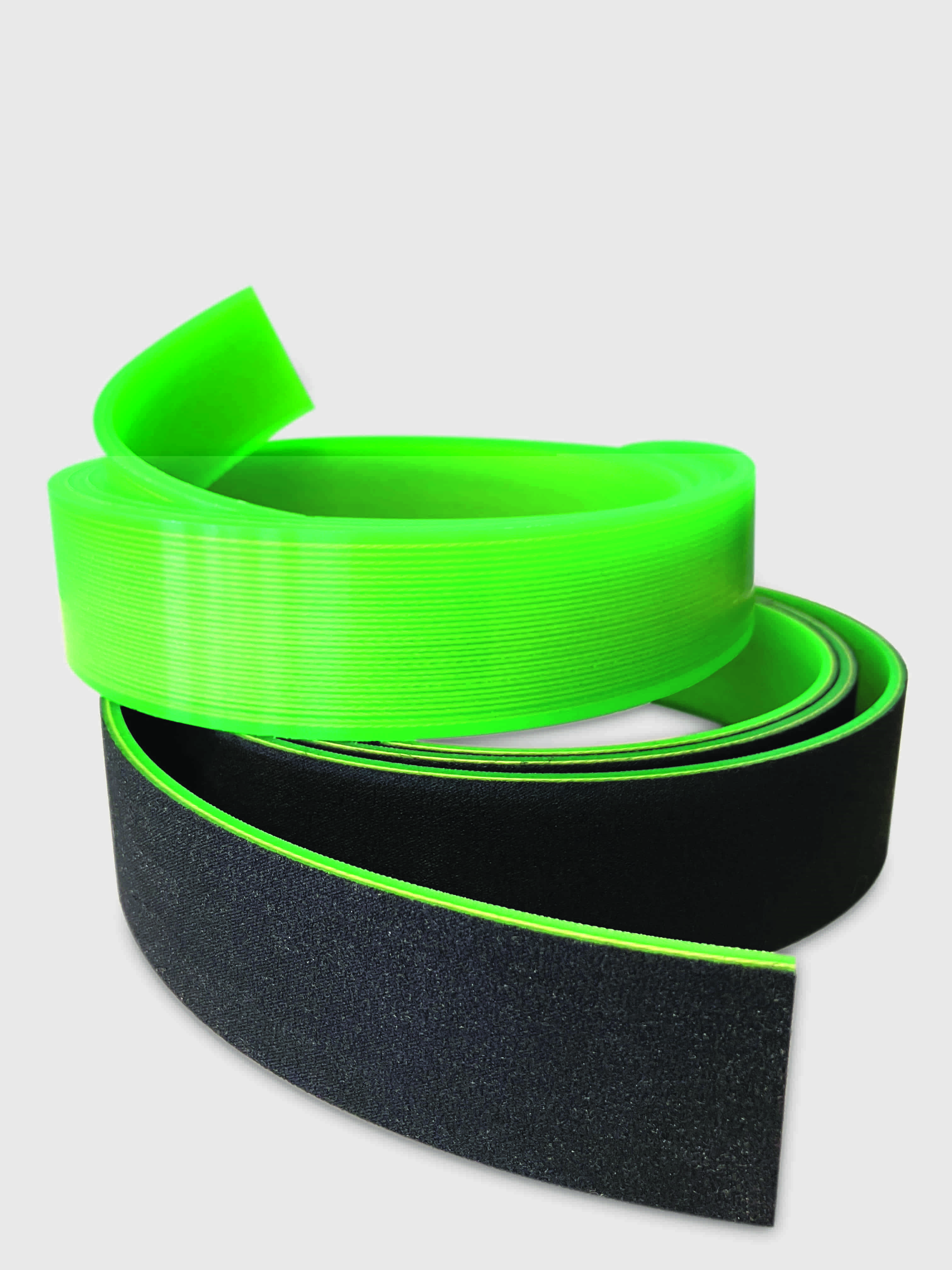

The belt exhibits flexibility while optimizing friction on metal rollers. This flexibility ensures smooth navigation through the twists and turns of the roller conveyors. The choice of belt material and design is crucial for achieving a balance—providing robust friction on metal rollers for secure item transfer and low friction on idlers to minimize energy consumption. MEGALINEAR MLR-45 is manufactured from polyurethane 85° ShA, in standard green and alternative version with black antistatic fabric on the bottom.

Características

MEGALINEAR MLR-45 is manufactured from polyurethane 85° ShA, in standard green and alternative version with black antistatic fabric on the bottom.

Componentes principales

Features:

• central aramid cords packed to avoid the possibility of cords at the sides,

• green translucent finish for easy wear detection,

• high friction surface,

• optional - black fabric antistatic to offer a conductive characteristic, reduce dust abrasion and lower friction

Characteristics:

Standard Width: 45 mm

Standard Length: 100 – 150 – 200 m (other lengths on request)

Thickness: 4.5 mm

Max traction load: 9600 N

Breaking strength: 38400 N

Working temperature: -25 / + 80 °C

Características técnicas y mecánicas

Flexibility & High-Performance

• high grip and less slip on the rollers

High Efficiency

• stable tension over time

• smooth running and designed for longer life

Less Maintenance

• easy installation

• fast and easy replacement on-site

• easily spliced using common splicing equipment

Energy Saving

• low energy consumption due to high flexibility

Cost Saving

• superior wear and abrasion resistance resulting in longer belt life

• improved resistance to ozone and temperature degradation

• increase flex life over time

• improved performance increasing machine run time